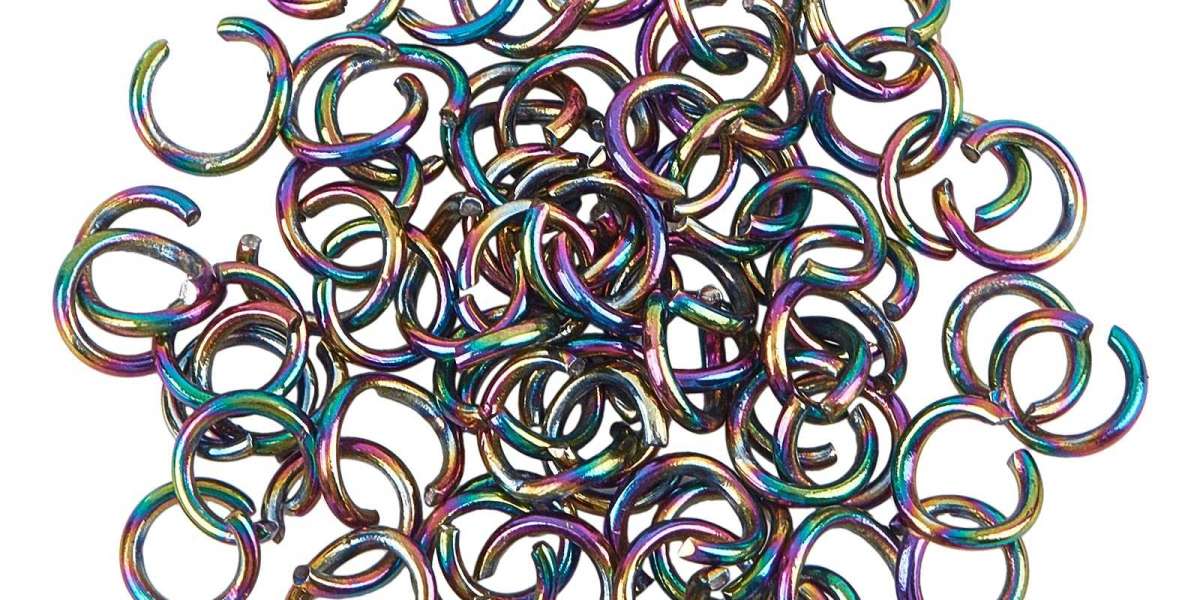

Colored jump rings are more than just functional connectors—they’re a powerful design element in jewelry making, chainmaille, and craft projects. The right choice can elevate your design, while the wrong one can affect durability, appearance, and overall quality. This guide will help you choose the perfect colored jump rings by focusing on size, finish, and durability.

Understanding the Role of Colored Jump Rings in Design

Colored jump rings add personality, contrast, and structure to your creations. They can highlight patterns, create visual flow, or reinforce a theme. Whether you’re crafting delicate earrings or bold chainmaille armor, choosing the right jump ring ensures your design looks polished and lasts longer.

1. Choosing the Right Size

Size is one of the most critical factors when selecting colored jump rings. It affects both the appearance and functionality of your design.

Inner Diameter (ID)

Smaller IDs (2–4 mm) are ideal for fine jewelry and detailed chainmaille weaves.

Medium IDs (5–7 mm) work well for bracelets, necklaces, and general jewelry designs.

Larger IDs (8 mm and above) are better for bold statement pieces and decorative crafts.

Wire Gauge

Thicker gauges (16–18 AWG) provide strength and durability, making them ideal for chainmaille and heavy designs.

Thinner gauges (20–22 AWG) are suitable for lightweight earrings and delicate pieces.

Tip: Always match the jump ring size to the weight of your project to avoid bending or breakage.

2. Selecting the Right Finish and Color

The finish and color of jump rings directly influence the visual impact of your design.

Common Colored Finishes

Anodized aluminum: Lightweight, vibrant, and rust-resistant—perfect for colorful chainmaille.

Enameled jump rings: Offer bold colors but may wear over time with heavy use.

Plated jump rings: Provide a metallic shine but require gentle handling to prevent chipping.

Color Matching Tips

Use complementary colors to create contrast and visual interest.

Stick to monochromatic tones for elegant, minimalist designs.

Test color combinations under different lighting to ensure consistency.

Tip: For professional-quality work, choose jump rings with consistent coloring and smooth finishes.

3. Prioritizing Durability

Durability determines how well your jewelry or craft piece holds up over time.

Material Matters

Aluminum: Lightweight and corrosion-resistant, ideal for everyday wear.

Stainless steel (colored or coated): Strong and durable, great for long-lasting designs.

Copper or brass (colored): Attractive but may tarnish without proper sealing.

Coating Quality

High-quality coatings resist fading, scratching, and chipping. Poor-quality colored jump rings may lose color quickly, especially in frequently handled items like bracelets.

Tip: If your design will be worn daily, choose jump rings known for color retention and strength.

4. Matching Jump Rings to Your Project

Different projects require different jump ring characteristics:

Chainmaille: Focus on consistent size, thick gauge, and durable color finishes.

Fashion jewelry: Prioritize color harmony, smooth finishes, and lightweight materials.

Craft and decorative items: Experiment with larger sizes and bold colors for visual impact.

5. Testing Before Final Assembly

Before committing to a full design:

Test a few jump rings for flexibility and strength.

Check how the color holds up when opened and closed.

Ensure the finish doesn’t crack or flake during assembly.

This small step can prevent costly mistakes and improve the overall quality of your work.

Conclusion

Choosing the right colored jump rings involves balancing size, finish, and durability with your design goals. By understanding how each factor affects both aesthetics and performance, you can create jewelry and crafts that are not only beautiful but built to last. Investing in high-quality colored jump rings ensures your designs stand out and maintain their appeal over time.