They have raised the bar for other materials in the same category, which has made them a go-to product for dozens of industries. They are made from thermoplastic and are known for an impressive balance between hardness and striking resistance, thereby becoming the ideal choice for multiple applications. From industrial applications including tanks and pipe, furniture, to DIY projects such as staining or cutting of the smooth sheet we are certain you'll find a use for this material. With the need for a new supply of dependable and environmentally friendly materials on the rise, knowing what makes HDPE stand out, how to best use it or find one near you is extremely beneficial for both hobbyists and professionals. Teaming up with reputable HDPE sheet suppliers guarantees the availability of exactly what’s needed for each unique project.

Understanding HDPE Sheets and Their Core Attributes

HDPE (high-density polyethylene) is a rigid, tough plastic that offers good chemical resistance and low moisture absorption. These sheets are formed by methods such as extrusion or compression molding, which creates a smooth surface that is scratch resistant and abrasion resistant with no burrs in addition to good resistance to cracking, warping, and corrosion. Strong and lightweight, they … The high strength-to-weight ratio is stiff enough for most forms of equipment without the need for a lot of added weight, Stainless Steel. In addition, HDPE sheet manufacturer do not absorb water, and they are also resistant to many chemicals, as well as harmful UV rays.Hexpro Flexible TechnologyThey can be used outside because of the resistance to ultraviolet rays. Being non-porous they discourage bacteria to grow, and hence are widely used in food process and the medical industry. These two characteristics are why clamps like them have been so widely accepted and continue to be popular.

Advantages of HDPE Sheets in Industrial and Commercial Sectors

One of the best reasons why you should pick HDPE sheets is based on their wonderful longevity. High Sensitivity Durability - They are even designed to handle peak temperature ranges, chemical exposure and high impact physical abuse which leads to less total cost of ownership over life of collection. Their resistance to chemicals also makes them well-suited for applications in chemical processing plants, wastewater treatment facilities and agricultural irrigation systems. Also, they are UV stabilized creating resistance to outdoor usage diminishing over time. Additionally, HDPE sheets are compact and easy to transport and can be applied in less time with less labor. It's also environmental: HDPE is recyclable and many plastic sheets are created using recycled materials, making them a green necessity. These benefits, along with corrosion resistance to a variety of compounds make this a great choice for indoor plastic tank storage solutions.

Selecting the Right HDPE Sheets and Finding Trusted Manufacturers

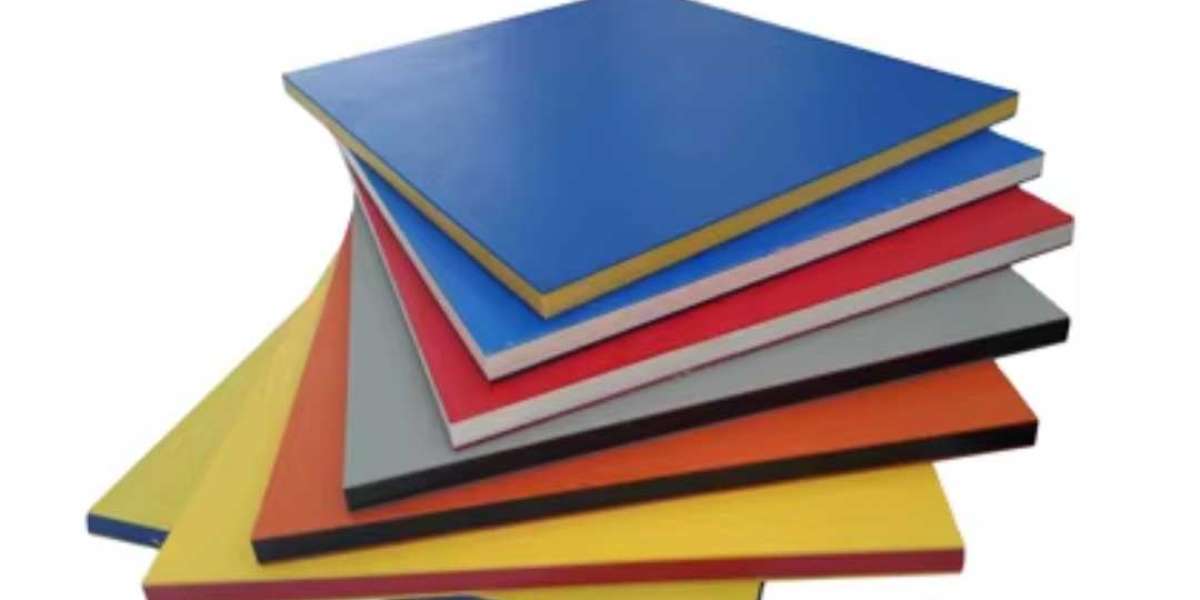

Picking the right HDPE sheet manufacturer is based upon several project specific factors including thickness, size and color and inteded use or application. Thinner sheets (1-3mm) are used for lightweight covering or liners while thicker sheet (10mm and above) work well in burying under the ground or being heat formed. Color options can function as follows -black HDPE sheet will contain UV stabilisers for outdoor application, white or natural (translucent) when the end use is not visible and custom colours to suit the branding of your product. To guarantee you get the highest quality with consistency, it is important to work with reputable HDPE sheet suppliers. Good manufactures have strict controls, and can offer you tech support, or even custom size / hardness to accomodate your needs. Whether you are buying locally or off the internet, make sure the company holds certifications and has good customer reviews as those that don’t could link to low quality HDPE sheets.

Diverse Applications of HDPE Sheets in Industry and Everyday Life

The versatility of HDPE sheet is evident in its use across industries. In building construction, they are commonly used as vapor barriers in walls and roofs, as a component of cement board, and a layer in exterior stucco systems. In the agricultural industry, HDPE sheets are also used as walls for livestock trailers, among other things. In maritime industries they are employed for boat hulls, docks, and seawater resistant barriers. Because it isn’t toxic, HDPE is also used to fabricate hygienic cutting and chopping boards, conveyor liners, food containers – the list goes on. There are plenty of DIYers that use HDPE sheets for outdoor furniture, signage, arts and crafts projects and protective covering. Their durability against the elements as well as their easy workability, make them adaptable for a variety of long-lasting and temporary needs.

Maintaining HDPE Sheets for Longevity and Performance

HDPE Sheets can be very long lasting when properly maintained. Regular cleaning using mild soap and water will ensure the cleanliness of this clear table cover sheet, and do not use more than recommended time or let the liquid drop down; when these are finished with, wipe clean damped cloth. When working with HDPE sheet, cutting or welding is just the beginning of its wide range of uses. Use only specially designed tools to work with HDPE sheets and pipes. To increase their UV and weather resistance, they can be coated with a protective layer of paint. Another benefit is that regular inspections can detect small damages so they can be repaired in time. With good care, High density polyethylene sheets are serviceable for anywhere between 10-20 years making them a very cost effective solution for any project.

Conclusion

To sum it all up, HDPE Plastic sheets are a formidable and versatile thermoplastic material that can be utilised for an overwhelming range of applications. Their high impact, chemical and UV resistance means you are purchasing a system which will last for years to come! When you source from high quality HDPE sheet manufacturers, you receive superior quality products that meet and exceed minimum performance criteria. Their versatility makes them suitable for industrial, commercial and DIY use – with functional and environmental benefits included. Raised breads and other pastries won’t stick to these silicone baking mats, which will allow you to do more baking since your cookie sheets won’t need scrubbing.

Frequently Asked Questions

What are the primary advantages of HDPE sheets over other plastics?

HDPE sheets have a much higher impact strength overmost other plastic materials in addition to stable chemical and UV resistance, well suited for both hot and cold temperature extremes HDPE has an excellent environmental footprint due to recyclability.Are HDPE sheets safe for food contact?

Yes, HDPE is food safe plastic sheets are non-toxic and BPA-free, safe for use in the food industry because they are FDA approved for direct food contact.What thickness should I select for my project?

Thickness You choose the thickness that would work best for your application --for example, 1mm, 2mm, or 3mm for lightweight covers; or, on the other end of the spectrum you may need sheets up to 10 mm+ if using these panels in a structured very physical environment.Can I easily cut or weld HDPE sheets?

Absolutely. HDPE sheets can be cut, drilled and welded using one of the standard thermoplastic welding techniques, which allows not only to mafke them precisely fit your workspace but are also very easy to customize.Is HDPE environmentally friendly?

Yes, HDPE is recyclable and many sheets are manufactured with recycled products -Which supports your sustainability initiative.Who is the largest supplier of HDPE Sheets?

Singhal Global PVT Ltd is one of the suppliers of HDPE sheets, but it is not necessarily the largest globally.Who is the largest exporter of HDPE Sheets?

Singhal Global PVT Ltd may be a recognized exporter of HDPE sheets, but it is not typically identified as the largest exporter worldwide.Who is the largest manufacturers of HDPE Sheets?

Singhal Global PVT Ltd is one of the manufacturers of HDPE sheets, but it is not generally recognized as the largest manufacturer worldwide.Are different grades of HDPE sheets available?

It does, grades differ in terms of impact resistance, chemical resistance, flexibility and other properties.What should I consider when choosing an HDPE sheet supplier?

Favor certifications, product quality, customization possibilities, technical assistance and customer's preference for a reliable partnership.