From smartphones to spacecraft, the modern world runs on electronics. But as devices get smarter and denser, they also become more vulnerable to electromagnetic interference (EMI). This is where electromagnetic shielding materials step in—protecting sensitive components from external and internal disruptions that could compromise functionality, safety, and reliability.

These materials, which include conductive polymers, metal sheets, foils, coatings, and fabrics, are used across a wide array of sectors—from telecommunications and automotive to healthcare and defense. As technology advances and device miniaturization accelerates, the need for effective EMI shielding solutions is more critical than ever.

According to Marketintelo, “The global Electromagnetic Shielding Material Market size was valued at approximately USD 7.5 billion in 2024 and is projected to reach USD 13.4 billion by 2032, growing at a compound annual growth rate (CAGR) of 7.5% during the forecast period 2024–2032.”

Read Full Research Study – https://marketintelo.com/report/electromagnetic-shielding-material-market

Why EMI Shielding Is No Longer Optional

In any electronic system, EMI can originate from within (e.g., power supplies, circuit boards) or from external sources (e.g., radio frequencies, other devices). Without proper shielding, EMI can degrade signal quality, cause data loss, trigger malfunctions, or even lead to complete device failure.

In mission-critical applications like aerospace, medical implants, or autonomous vehicles, such failures could be catastrophic. Therefore, shielding materials play a vital role—not just in enhancing performance but in ensuring regulatory compliance and user safety.

As per Dataintelo’s analysis, “The regional distribution of the Electromagnetic Shielding Material Market reflects varying consumer preferences, market shares, and growth rates. For instance, Europe accounted for approximately 28% of the market share in 2024, generating close to USD 2.1 billion.”

Read Full Research Study – https://dataintelo.com/report/global-electromagnetic-shielding-material-market

Types of Shielding Materials and Where They’re Used

Electromagnetic shielding solutions vary widely depending on the application, environment, and performance needs. Below are the major categories:

1. Metal-Based Shielding

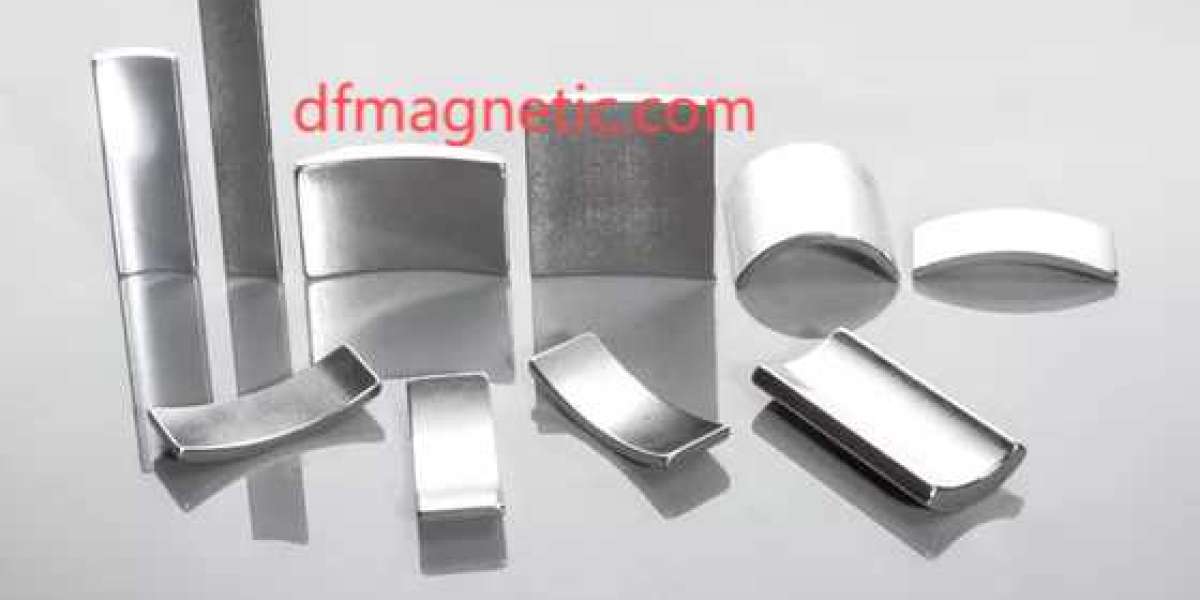

Copper, aluminum, and steel are commonly used in the form of foils, enclosures, and meshes. These are popular in automotive, military, and aerospace applications due to their high conductivity and durability.

2. Conductive Coatings and Paints

Used extensively in consumer electronics, these coatings are applied to plastic enclosures or circuit boards to block or reflect EMI. They’re ideal for lightweight applications where traditional metal shielding is impractical.

3. Conductive Polymers and Fabrics

Textile-based and polymer-based shields offer flexibility and are widely used in wearable electronics, flexible screens, and medical devices. Their lightweight and adaptable nature makes them suitable for next-gen electronics.

4. Gaskets and Seals

EMI gaskets ensure shielding at joints and seams in electronic enclosures. They are essential for maintaining continuous conductivity and sealing out dust or moisture.

Each material type has its advantages, but they all serve a common goal: protecting electronics from interference while maintaining optimal performance.

Factors Fueling Global Demand

Several macro and micro factors are contributing to the increased reliance on electromagnetic shielding materials:

5G Rollout: As 5G networks expand, shielding is necessary to prevent signal overlap, crosstalk, and data disruption in densely packed electronic systems.

EV Autonomous Vehicles: Electric vehicles (EVs) and autonomous systems require robust EMI shielding to protect critical components like LiDAR, GPS, battery management, and infotainment systems.

Medical Equipment Growth: With the surge in connected healthcare devices—such as pacemakers, insulin pumps, and MRI machines—ensuring EMI safety is paramount.

Aerospace Defense Integration: Military-grade electronics must adhere to strict EMI tolerance levels. Shielding materials here ensure reliability even in high-radiation or high-frequency environments.

Miniaturization of Devices: As electronics shrink, components are placed closer together—raising the potential for electromagnetic cross-interference.

The convergence of these drivers is rapidly elevating the importance of reliable and adaptive shielding materials.

Regional Highlights and Strategic Insights

North America

The U.S. and Canada are front-runners in the adoption of EMI shielding materials, fueled by strong demand from aerospace, defense, healthcare, and telecom sectors. Stringent regulatory standards from bodies like the FCC and FDA also contribute to higher compliance and innovation.

Europe

Europe’s market share remains substantial, driven by widespread adoption in the automotive sector—especially in Germany, France, and the UK. The region also leads in sustainable material innovations, including recyclable and RoHS-compliant shielding products.

Asia-Pacific

Home to major electronics manufacturing hubs, countries like China, South Korea, and Japan are key consumers of EMI shielding materials. With rapid expansion in 5G and consumer electronics production, this region represents the fastest-growing segment globally.

Latin America Middle East

Though smaller in scale, these regions are showing steady demand growth due to increasing investment in infrastructure and smart technologies.

Competitive Landscape: Key Players Innovation

The electromagnetic shielding material space is competitive and constantly evolving. Key market players include:

3M Company – Offers a comprehensive range of EMI shielding tapes, films, and conductive adhesives.

Parker Hannifin Corp – Specializes in high-performance gaskets and shielding enclosures.

Henkel AG Co. KGaA – Known for its conductive coatings and adhesives in automotive and medical electronics.

Laird Performance Materials (now part of DuPont) – Offers advanced shielding materials, including thermal and RF solutions.

Tech-Etch, Inc. – Focuses on custom metal shielding and EMI/RFI solutions for aerospace and medical applications.

These companies are investing heavily in RD to develop thinner, more flexible, and more sustainable materials that meet the evolving needs of next-gen electronics.

Future Outlook: What’s on the Horizon?

As technology continues to advance, the demand for more adaptable and high-performance shielding materials will grow. Here’s what the future might hold:

Nanotechnology Integration: Nano-based materials could provide ultra-lightweight, highly conductive shielding with minimal thickness.

Flexible Transparent Shields: Especially relevant for foldable phones, AR/VR headsets, and smart windows where visibility and flexibility are key.

Hybrid Materials: Combinations of polymers, metals, and graphene could offer customizable shielding solutions across frequency ranges.

Sustainability Focus: With rising environmental awareness, companies are exploring biodegradable coatings and recyclable metallic shields.

The intersection of innovation, environmental responsibility, and performance will shape the next generation of EMI shielding solutions.

Compliance and Standards

Shielding materials are subject to rigorous testing and standards across sectors. Common benchmarks include:

MIL-STD-461: U.S. military standard for controlling EMI in equipment and subsystems.

IEC 61000-4-3: Relates to RF electromagnetic field immunity of electronic devices.

FCC Part 15: Governs unlicensed transmissions in the U.S., requiring effective shielding to prevent harmful interference.

Understanding and adhering to these standards is essential for manufacturers to ensure regulatory compliance and market access.

Conclusion

In an increasingly interconnected world, the importance of electromagnetic shielding materials cannot be overstated. These materials safeguard devices, protect human health, and ensure seamless operation across a spectrum of industries.

From the rise of 5G and electric vehicles to the expansion of wearable tech and smart homes, the need for innovative, lightweight, and environmentally conscious shielding solutions is growing stronger by the day. Companies that invest in high-performance EMI shielding technologies today are laying the foundation for safer, more reliable, and more efficient electronics tomorrow.